Industrial experts say that once you start using a plasma circle cutter you won’t switch back to any oxy-fuel cutting grinding discs or any other cutters. It is an amazing tool for all workplaces which helps in metal cutting. It is easy to use and cheaper to run compared to other oxy-fuel cutting. Now, let’s go through this brief guide about plasma cutting.

What does it mean?

The way to cut any metal that conducts electricity. Operating a hand-held plasma cutter is very simple.

How does it work?

It works on the DC voltage to ionise the atoms and creates an arc with the help of heat compressed air to a high temperature. The small jet of plasma pushes through and melts the metal and pushes it away. When you compared the oxy-fuel and comparative results it is highly focused.

Steps to set up a plasma cutter

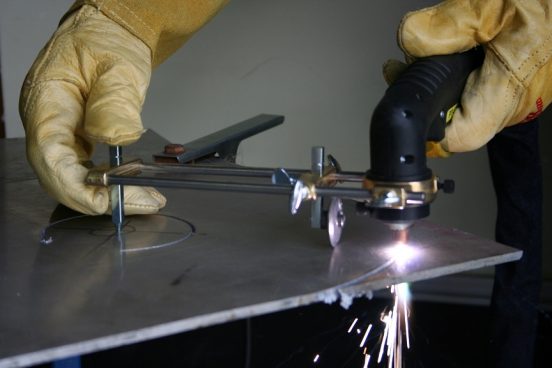

To cut the circle starting from the edge of the job or drill a hole in the middle of the job. Take the circle cutting kit and make the shape you need using a template. Here are the six easy steps for setting up your plasma cutter.

- First, connect the cutter to a suitable air compressor.

- Supply the correct voltage described in the product manual.

- Put it on the ground to lead to your workpiece.

- Add torch to the machine

- Now select the amperage according to the material

- At last, start the torch and move it across the work as the cutter cuts the arc in the metal.

Plasma cutters are fairly portable because there are no heavy gas bottles present to lug around. The great benefit is the minimized heat which is an affected zone with small cut width compared to the oxy-fuel cutting.

Steps for cutting circle using a plasma cutter

You can easily cut the perfect circle with a cutter after you attached the nozzles of the cutter. Simply find the circle’s centre and punch the drill to allow the centring pin to sit into a attach through the metal sheet.

Step 1: Tools and material

Gather all the tools and materials listed below for cutting the perfect circle with a plasma cutter.

Tools:

- A saw

- Glue

- Drill and drill bits

- Fine grit sandpaper

- A measuring device, like callipers or ruler

- A pencil or marker

Materials:

- Flat wooden board

- A ball bearing

- A nut and bolt (keep extra nuts)

- A small neodymium magnet

Step 2: Drill the holes

- To drill the holes first find out the centre of the wood and mark it with the help of a marker or pencil.

- Now, measure out the distance using a radius for your circles which alternates between two marked lines and drill out the holes.

- At last, finish the holes by sanding them with the help of sandpaper.

Step 3: Gluing

For sticking the ball bearing take the bearings and line up them above the centre hole for marking the position. Now, take glue and stick a magnet to the bottom of the bolt’s head. Moreover, ensure that the glue doesn’t contact the bearings.

Step 4: Finishing

The last and final step is finishing. Once your glue has been set, your plasma circle guide is ready to use and assemble.

The safety equipment you should use

When you are working with a cutter ensure that you gear up all the types of equipment and instruction. Because it is essential to know that this machine can cause serious injury if you don’t use it properly. However, with a basic plasma circle cutting guide and rules, it is safe to use this tool. Here is some safety gear which is recommended by experts.

- To protect your hands wear welding gloves.

- Helmet to protect eyes and face

- Welding beanie to protect your hair from spark

- Jacket to protect arms and torso

- Welding leather to protect your legs or a set of jeans

- Laced or tied boots will protect your feet from the spark.

- Fire extinguisher

Metal cut by the cutter

It can cut all the metals that conduct electricity, such as

- Copper

- Brass

- Steel

- Stainless steel

- Aluminium

- Other conductive metals

Which cutting machine do you need?

Before, purchasing your cutting machine first find out the answer to the following question.

- What is the input voltage of your workshop?

- What will be the maximum thickness of the metal you can cut?

- Whether you have the air compressor or not?

At last, look the options which are available in the market.

Conclusion

So, with the help of this guide, you can easily purchase the plasma cutting machine. This machine will reduce the manpower and efforts to create a perfect circle.

Follow us